A new scientific paper has been published by AIRE’s partner DTU. It appeared in the Proceedings of the 2025 Wind Energy Science Conference and was presented at the AIAA Aviation Forum and Ascend 2025, a conference organised by the American Institute of Aeronautics and Astronautics (AIAA) held in Las Vegas, from 21 to 25 July 2025.

The basics

As discussed in previous blog posts, roughness and erosion on the leading edge of wind turbine blades affect their aerodynamic performance. In this study, the authors develop a workflow to extract and digitise roughness topographies obtained from high-resolution 3D scans and apply them to aerofoil surfaces for evaluation through high-resolution 3D Computational Fluid Dynamics (CFD) simulations.

Process

The researchers performed 3D scans of the leading edges in operation and created two types of roughness topographies: one with moderate surface damage and another with deeper erosion. These geometries were digitally applied to typical wind turbine aerofoils with varying relative thicknesses.

High-resolution 3D simulations were then carried out using a boundary layer transition model (γ Reθt) to analyse turbulence onset in the boundary layer at different Reynolds numbers. In addition, 2D slices of the same geometries were simulated to compare with the 3D results and assess the accuracy of using simplified representations.

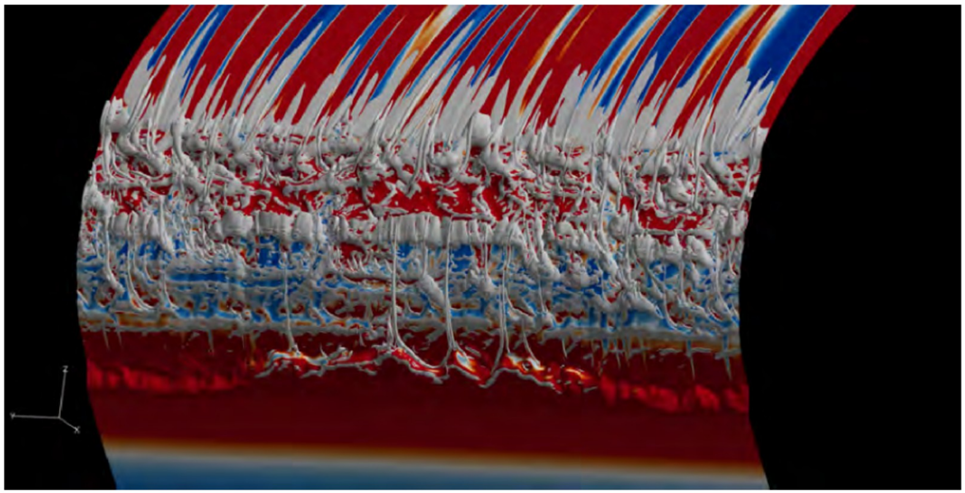

Figure 1: Vortices showing laminar and turbulent flow on the surface.

The image shows a high-resolution 3D simulation of a wind turbine aerofoil with actual leading-edge roughness. The white vertical structures represent vortices and three-dimensional airflow features generated by the leading-edge irregularities. The aerofoil surface is coloured according to the flow type: blue indicates laminar flow regions (where the air moves smoothly), while red represents turbulent flow (where the air mixes and drag increases). The simulation was conducted at a 6° angle of attack and a Reynolds number of 3 million, typical operating conditions for a wind turbine blade.

Main results

The results show that even moderate leading-edge damage can alter the airflow around the blade, increasing drag and slightly reducing performance. Deeper damage has an even greater effect, particularly near the stall point, compromising overall efficiency. Furthermore, the 3D simulations demonstrated that 2D approximations do not fully capture the actual impact of real roughness and erosion, highlighting the importance of analysing blades in three dimensions to obtain accurate data.

For the full publication, you can access it here.

Author: Oria Pardo

Editor: Alexander Meyer Forsting

January, 2026